[rev_slider_vc alias=”main-slider”]

Mold Flow Simulation & Rapid Prototypes

We utilize a variety of methods to produce rapid prototypes and tooling. This includes the following:

- The ability to work with CAD/CAM files of any file type.

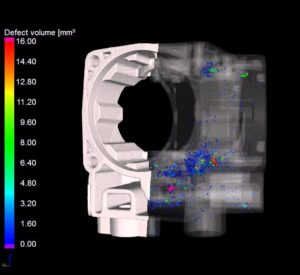

- Mold Flow Simulation to show how the mold will fill, solidify, and cool—thus reducing the risk of defective parts.

- Value engineering to help reduce cost throughout the manufacturing process.

- 3D Printing / Additive Manufacturing, allows us to produce rapid prototypes that help ensure fit before investing in costly tooling and fixtures.

- Partial Design: We provide expert advice to our customers for new tool builds.

Electric and hybrid powertrains are gaining importance and popularity. In the automotive and heavy trucking industries, the technological move from the combustion engine towards electrified and other alternative drives has greatly impacted the die casting industry.

Lightweight Castings

Lightweight castings are becoming more critical as industries shift towards powertrain electrification.

Key Benefits of Aluminum Die-Castings

- Complex

- High-Quality

- Thin-Walled

- Lightweight

- Good Mechanical and Physical Properties

Die casting is one of the most efficient and environmentally friendly manufacturing methods available today. Some of the highest-quality die casting materials are entirely recyclable and meet the tenets of the “reduce, reuse, and recycle” philosophy.

About Northwest Die Casting